When I first heard the term ‘breadboard’ when reading about electronic circuits, I thought about bread of course and some great bread making recipes. I must have been hungry!

For electronic recipes 🙄 (i.e. circuits), originally a smooth piece of wood (literally a breadboard with nails and wiring) was used as a surface for assembling/wiring electronic components. We still use the term breadboard today although the synonym protoboard is also used.

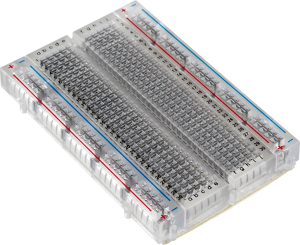

The breadboard of today is reusable and does not use solder which makes it a good experimental tool to prototype circuits. It consists of a perforated block of plastic with numerous metal spring clips under the holes and comes in various colors and sizes (i.e. number of holes):

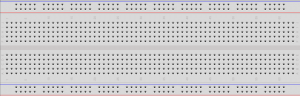

My favorite one is transparent so you can see the spring clips. It has 400 holes and looks like this:

On this breadboard there are two identical sides separated by the middle notch. Each side has 200 holes ( each divided into two ‘strips’). One strip is called the terminal strip and the other is called a bus strip (which contains two columns: one for ground – and one for a supply voltage +.) The clips on the right and left of the middle notch are each connected in a radial way; five clips (i.e., beneath five holes) in a row on each side of the notch are electrically connected. On the bus strip the whole row (+ or -) is electrically connected.

Breadboards usually have an adhesive backing and can be interlocked for larger projects. The spacing between the holes is typically 0.1 in (2.54 mm). Integrated circuits (ICs) in dual in-line packages (DIPs) can be inserted to straddle the centerline/notch of the block. Interconnecting wires and the leads of components (such as capacitors, resistors, and inductors) can be inserted into the remaining free holes to complete the circuit. Connecting wire should be 22 AWG (0.33 mm2) solid copper. If you have any CAT5 cable around, that is perfect.

Just cut to the length you need unravel the wire and straighten it out. The wire ends should be stripped 3⁄16 to 5⁄16 in (4.8 to 7.9 mm).

Recent Comments